A few weeks ago the London Metal Exchange announced that it was temporarily suspending trading in nickel sales contracts in the face of «unprecedented price movements».

Its price more than doubled to over $100,000 per tonne. The reason was due to Russia’s decision to ban commodity exports.

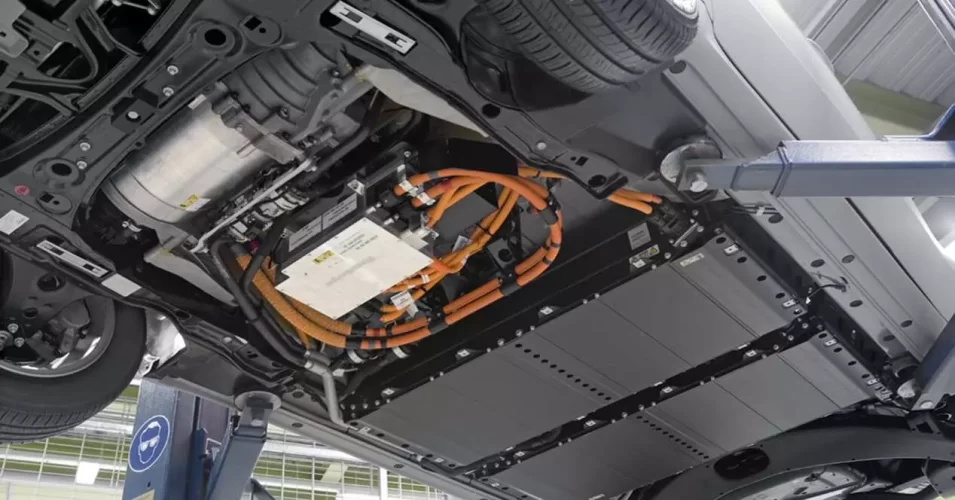

One of the few carmakers that use the mineral is Tesla, but it has been cutting back since last year, when its batteries needed 80 per cent nickel, 10 per cent manganese and 10 per cent cobalt.

But the US company decided to change its philosophy, because the raw material problem was already a well-known problem for the industry. Therefore, the cars produced by Tesla started using iron-phosphate batteries.

This paradigm shift came as a result of the price increase that happened in 2021 and not in this last war, as Jaime Alee, a market consultant, explains to Portal Movilidad.

During 2021 there was an excess demand for electric cars. It was expected to reach 4.6 million vehicles sold and reached 6.3 million.

This disruption implied an excess demand in the supply chain and raw material prices went up, mainly Lithium and Nickel.

In addition, the new curve this year will reach more than 8.1 million and next year will exceed 10 million electric vehicle units globally, an achievement it expected by 2025.

«So the supply chain supply is expected to tighten in about three years for lithium and a couple of years for nickel as it has a substitute which does not exist with lithium,» says Alee.

In the last month, a tonne of nickel has exceeded US $120,000. The price a year ago was 25% less.

This is because Russia accounted for about 9.2% of the world’s total nickel mine production in 2021 and has 7.5 million tonnes of the metal in its reserves.

The rising cost of the electric car, due to the effect of the nickel makes for an extra 300 dollars in price product price. of demand for nickel prices.

«We are talking about electric vehicles costing 40,000 dollars, we should not exaggerate. The price is also going up for bulk purchases, but it’s not that exaggerated,» Alee assumes.

However, if this situation continues in the long term, it would complicate the picture because supply is increasing. But on the other hand, «battery technology is changing a bit,» says the consultant.

The situation in the next couple of years «will stabilise quite a bit» and will probably see much more use and consolidation of iron-phosphate batteries, a technology that has been improved over time.

The vast majority of Chinese electric cars use iron-phosphate batteries, two abundant minerals. They have already been tested and have shown positive results in terms of energy efficiency.